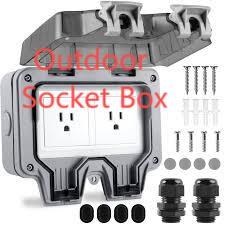

Nante Outdoor Socket Box Supplier: Installation Tips

Selecting reliable outdoor power hardware is critical for any installation, and choosing an Outdoor Socket Box Supplier early in the design process helps define expectations for performance and service. When project teams evaluate options, specifying the correct Outdoor Socket Box Supplier at tender stage reduces substitution risk, clarifies warranty coverage, and ensures the chosen products meet site-specific exposure and mounting requirements.

Understanding ratings and what they guarantee

Ingress protection ratings (IP) and equivalent regional standards communicate how a box will perform under dust, rain, or hose-directed spray. IP66 and IP67 indicate different levels of water resistance; NEMA classifications describe performance against corrosion, impact, and environmental contaminants in certain jurisdictions. Pay attention to test conditions in manufacturer data sheets — a rating assumes factory-installed seals, specified fasteners, and the original cover configuration. Any field changes (extra cable entries, alternate glands) can reduce the effective protection and should be validated.

Material choices and corrosion resistance

The expected environment dictates material selection. Coastal or chemically aggressive sites usually require high-grade stainless steel or specially treated alloys to resist chloride and sulfide attack. Powder-coated aluminum offers a lightweight, thermal-dissipating choice for many inland installations, but ensure pretreatment processes and paint chemistries are compatible with the expected UV and pollutant exposure. Thermoplastics and fiberglass-reinforced enclosures may suit lighter loads and corrosive steam environments, but verify long-term UV resistance and mechanical strength for areas with frequent mechanical impact.

Mounting, reinforcement, and tamper protection (Nante options)

Proper mechanical installation matters as much as the enclosure spec. Mounting points should transfer loads to structural members rather than rely on thin cladding or drywall. Reinforcement plates behind mounting points prevent deformation from repeated plug actions. In public-facing or high-traffic areas, consider tamper-resistant fasteners, lockable covers, and captive screw designs that maintain weather seals while deterring unauthorized access. Where available, choose models that integrate with standard mounting brackets and offer optional backing plates to simplify retrofit installations.

Cable entry, gland selection, and maintaining seals

Gland selection is a common source of failure. Choose glands sized for the actual cable diameter and rated for the enclosure’s IP classification; under- or over-sized glands compromise sealing. Use proper strain relief to prevent conductor movement at terminals, which otherwise leads to fatigue and elevated contact resistance. For multi-cable installations, a modular gland plate reduces the need for ad hoc drilling on site and preserves factory-level sealing integrity. Finally, inspect gland threads and torque values during commissioning to ensure compression is consistent with manufacturer guidance.

Commissioning, maintenance, and lifecycle planning

A thorough commissioning sequence documents baseline measurements and helps catch installation issues early. Perform continuity, polarity, and insulation resistance tests, and record terminal torque and initial contact resistance values. Schedule inspections based on environment—coastal and chemical plants typically require more frequent checks than dry indoor areas. Maintain a small inventory of critical spares (gaskets, glands, common terminal blocks) to speed repairs. Track maintenance in a simple log, noting seal replacements and any ingress events to inform future procurement decisions and warranty claims.

Troubleshooting common field problems

The most common field failures involve water ingress, loose terminations, and mechanical damage. Thermal imaging quickly locates hot spots caused by elevated resistance. If corrosion is present at contacts, replace the affected contact set rather than attempting abrasive cleaning that removes protective plating. For persistent ingress, inspect mating surfaces and gland compression; hardened or compressed gaskets rarely return to specification and should be replaced. Document any repairs and communicate lessons learned to procurement teams to adjust future specifications.

Choosing the right outdoor socket box requires a systems-level approach: match electrical ratings to load, select materials that resist the local environment, enforce correct installation practices, and plan for realistic maintenance intervals. Early involvement of procurement, maintenance, and installers reduces surprises during commissioning and improves long-term reliability. For a concise technical overview and industry guidance on outdoor socket boxes, visit https://www.nante.com/news/industry-news/what-is-an-outdoor-socket-box.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness