Shanghai MSD’s Expertise in High-Performance PVC Inflatable Materials

In modern manufacturing, PVC Inflatable Fabric has become an essential material for products that demand strength, flexibility, and long-term durability. From water sports equipment and outdoor tents to rescue rafts and floating platforms, this material offers an ideal balance between functionality and affordability. Its structure — a tightly woven base fabric coated with layers of polyvinyl chloride — provides outstanding performance in diverse environments. As industries continue to innovate, the use of PVC-coated materials is reshaping how inflatable products are designed and used.

One of the primary advantages of this fabric is its combination of strength and elasticity. The coating creates a smooth, airtight surface that prevents air leakage, while the inner textile core adds the necessary tensile strength to withstand pressure and impact. This dual-layer design ensures that products made from it can handle both internal air pressure and external environmental stress. For example, inflatable pontoons and rafts used in rescue operations must endure friction against rough surfaces and unpredictable weather conditions. PVC-coated materials provide this level of reliability, making them a preferred option across industries that require dependable performance.

Another reason for its popularity is its resistance to environmental challenges. Unlike untreated fabrics, PVC-coated materials resist water, oil, salt, and most chemical exposures. This makes them ideal for marine and outdoor applications, where they often encounter harsh sunlight, humidity, and temperature fluctuations. The UV resistance of the PVC coating ensures the fabric maintains its color and mechanical integrity, even after extended exposure to sunlight. This is especially valuable for products such as advertising inflatables, which are displayed outdoors for long periods.

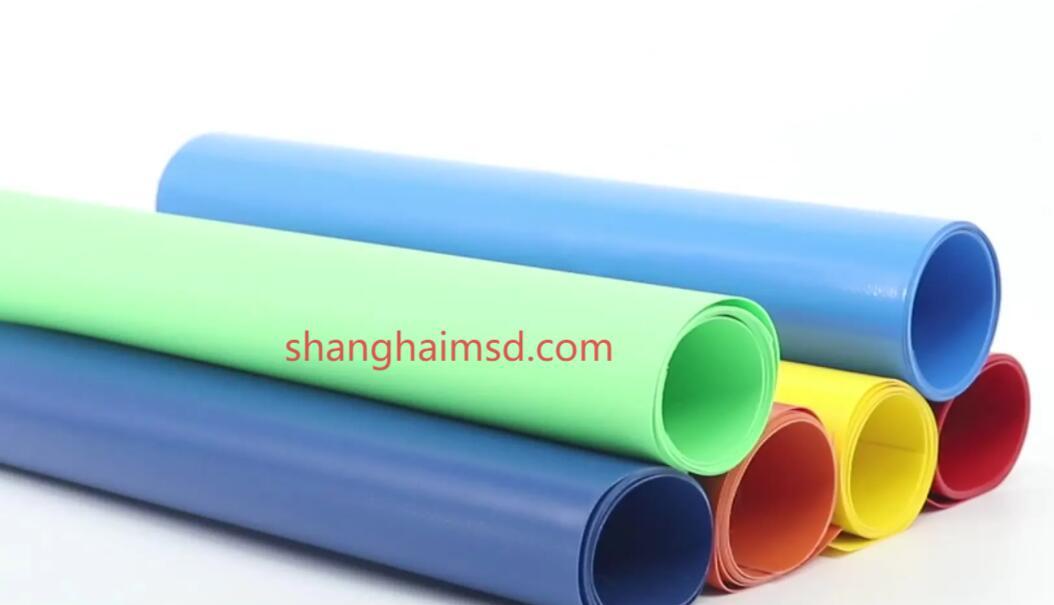

In terms of handling and production, manufacturers appreciate the material’s ease of processing. It can be heat-sealed or welded with precision, creating airtight joints that enhance the reliability of the final product. This process eliminates the need for stitching, which can weaken seams and allow air to escape. As a result, items made with this type of fabric are more durable and require less maintenance over time. Additionally, PVC-coated textiles are available in a wide variety of colors, finishes, and thicknesses, giving designers creative flexibility without compromising performance.

When compared to other materials such as TPU (thermoplastic polyurethane) or Hypalon, PVC-coated fabrics offer distinct advantages. TPU is known for its elasticity and resistance to low temperatures, but it tends to be more expensive and less UV-stable. Hypalon, while extremely durable and resistant to chemicals, has been gradually phased out due to environmental concerns and higher production costs. PVC-coated fabrics, on the other hand, provide a more economical and versatile solution without sacrificing mechanical strength or weather resistance. Their balance between quality and cost makes them the material of choice for both industrial and recreational uses.

Another area where this fabric excels is portability. Products such as inflatable boats, air beds, and portable shelters benefit greatly from the lightweight yet tough properties of PVC-coated textiles. They can be deflated, folded, and transported with ease, allowing for flexible storage and quick deployment. This convenience has made them increasingly popular in the leisure, defense, and emergency response sectors.

Sustainability is also becoming an important consideration in the industry. Many manufacturers, including those partnering with global suppliers, are now investing in eco-friendly coatings and recycling programs to reduce waste. With ongoing innovations in production methods, the future of PVC-coated materials is shifting toward greater environmental responsibility while maintaining their unmatched performance.

Shanghai Ming Shida International Trading Co. has become a key supplier in this evolving field, offering advanced materials for a wide range of inflatable products. The company focuses on providing PVC-coated fabrics with superior strength, excellent weather resistance, and consistent quality control for global markets. To explore more about PVC Inflatable Fabric and its role in making inflatable boats stronger and more reliable, visit https://www.shanghaimsd.com/news/industry-news/pvc-inflatable-boat-fabric-the-core-material-that-make-inflatable-boats-stronger.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness