How Modern Design Relies on PVC Inflatable Fabric Technology

In recent years, PVC Inflatable Fabric has gained widespread attention as industries seek materials that combine strength, adaptability, and cost-efficiency. This fabric, created by coating a textile base with polyvinyl chloride, offers a unique balance between toughness and flexibility. Its ability to endure demanding conditions makes it indispensable for products such as inflatable tents, life rafts, water parks, and even temporary architectural structures. As design requirements evolve, this versatile material continues to play a leading role in redefining inflatable technology.

A major factor behind its growing popularity is its exceptional structural integrity. The PVC coating creates an airtight and waterproof layer that prevents leaks and resists moisture absorption. This is especially critical for marine and outdoor applications, where constant exposure to water and sunlight can quickly degrade unprotected fabrics. By maintaining shape and elasticity under pressure, PVC-coated textiles help ensure that inflatable products perform reliably over extended periods. From rescue boats to industrial storage tanks, this material provides both security and consistency in the most demanding environments.

In terms of mechanical performance, the fabric demonstrates impressive resistance to abrasion, tearing, and punctures. Inflatable products are often subjected to rough handling and harsh surfaces, yet PVC-coated materials can withstand repeated use without significant wear. The reinforced fabric core, usually made of polyester or nylon, adds internal strength while keeping the overall structure lightweight. This combination of lightness and toughness enables manufacturers to produce durable products without compromising mobility or convenience.

Another notable strength of this material lies in its ease of fabrication. PVC-coated textiles can be heat-welded or high-frequency welded, creating perfectly sealed seams without the need for stitching. This method enhances airtightness and prevents weak points that might otherwise lead to air loss. Manufacturers value this efficiency, as it not only improves product reliability but also speeds up the production process. The result is a consistent, high-quality material that reduces maintenance costs and extends product lifespan.

When compared to alternatives such as TPU (thermoplastic polyurethane) and neoprene, PVC-coated fabrics stand out for their balance of price and performance. TPU may offer better elasticity and cold resistance, but it often comes at a higher cost and requires more complex manufacturing. Neoprene, though durable, tends to be heavier and less resistant to UV radiation. PVC-coated materials deliver strong overall performance across all key parameters — water resistance, UV stability, and mechanical strength — at a more affordable production cost. This makes them particularly attractive for large-scale applications like inflatable shelters and recreational equipment.

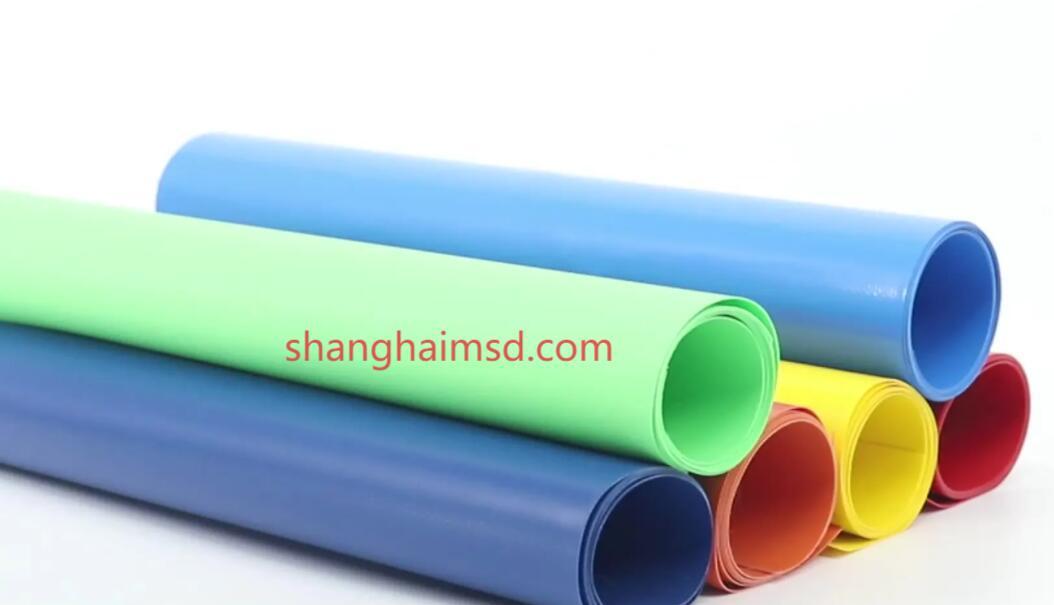

The versatility of this fabric also extends to design. It can be produced in various thicknesses, colors, and finishes, allowing for both functional and aesthetic customization. For example, matte finishes are preferred for outdoor tents to reduce glare, while glossy coatings enhance appearance for promotional inflatables. Additionally, anti-fungal and flame-retardant treatments can be applied to meet specific safety or environmental standards, expanding its usability in professional and industrial settings.

In the context of sustainability, modern manufacturers are exploring eco-conscious adaptations of PVC-coated materials. Some companies have introduced recyclable coatings or alternative plasticizers that minimize environmental impact. This shift reflects a growing awareness in the textile and manufacturing industries, where balancing durability with sustainability is becoming increasingly important.

Shanghai Ming Shida International Trading Co. continues to be a leading supplier of high-performance materials for inflatable products worldwide. With a commitment to quality and innovation, the company provides PVC-coated fabrics designed to endure demanding conditions and deliver long-term reliability. To learn more about PVC Inflatable Fabric and how it strengthens inflatable boat construction, visit https://www.shanghaimsd.com/news/industry-news/pvc-inflatable-boat-fabric-the-core-material-that-make-inflatable-boats-stronger.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness